Essential Devices and Techniques for Reliable Packaging Machine Repair

Essential Devices and Techniques for Reliable Packaging Machine Repair

Blog Article

Effective Ways to Troubleshoot Common Issues in Product Packaging Maker Procedure

In the realm of manufacturing and production, making certain the seamless operation of packaging makers is paramount to preserving effectiveness and conference target dates. Nonetheless, also the most advanced devices are not unsusceptible to coming across usual concerns that can interfere with the whole production process. Dealing with these difficulties swiftly and effectively is essential to reducing downtime and making best use of output. By implementing an organized strategy to troubleshooting and preemptive upkeep, operators can not only address concerns without delay however likewise avoid potential troubles in the future. Allow's check out some efficient approaches that can aid in quickly fixing typical problems in product packaging maker operation.

Identifying Common Product Packaging Device Issues

When fixing product packaging device troubles, it is essential to properly identify typical concerns that might occur throughout the product packaging process. One usual problem come across in packaging makers is improper securing.

In addition, problems with sensing units can disrupt the packaging procedure by failing to discover items or causing wrongly. packaging machine repair. Electric issues, such as malfunctioning circuitry or power supply concerns, are also typical wrongdoers behind packaging machine failures. Comprehending and immediately resolving these usual problems are important for preserving the effectiveness and dependability of product packaging procedures. By determining these problems early, drivers can stop downtime, lower item waste, and make sure the smooth performance of product packaging machinery.

Performing Regular Upkeep Checks

On a regular basis conducting extensive upkeep checks is vital for ensuring the ideal efficiency and long life of packaging devices. In addition, checking and calibrating settings associated to temperature, speed, and stress can assist preserve the equipment's efficiency and precision.

Additionally, performing normal inspections of electrical connections and controls can assist stop electric malfunctions and make sure the safety and security of the device drivers. Recording maintenance tasks and maintaining thorough documents of parts substitutes and repair work can help in tracking the maker's efficiency gradually and determining any type of persisting concerns. Inevitably, a positive technique to regular maintenance checks is critical in making the most of the productivity and reliability of packaging equipments.

Repairing Electric and Mechanical Problems

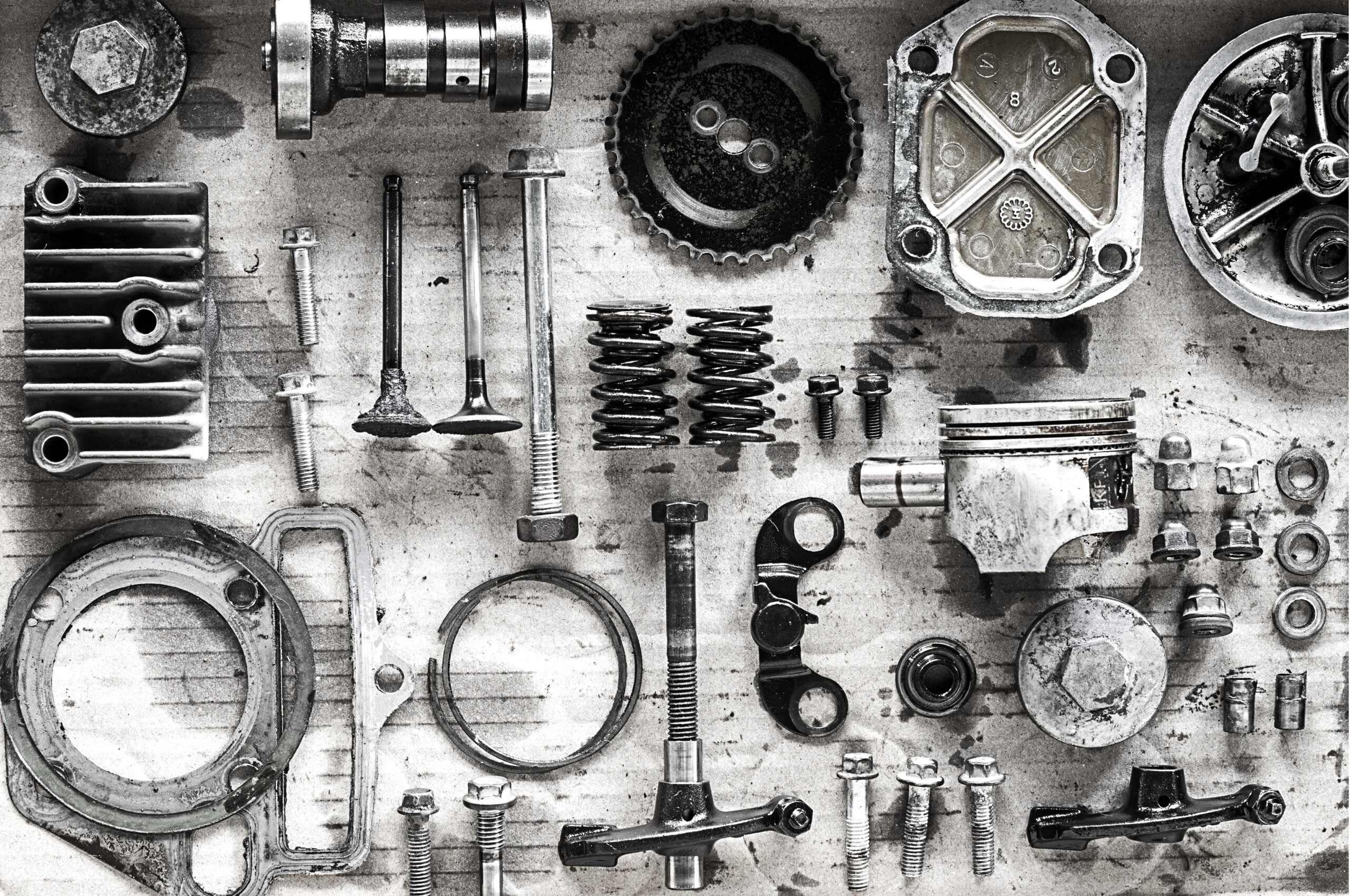

Efficient troubleshooting of electrical and mechanical issues in packaging equipments needs a systematic strategy and a deep understanding of the maker's components and procedure. When facing electric problems, beginning by inspecting source of power, connections, and control board for any type of visible damages or loosened links. Utilizing a multimeter can aid determine electric faults such as open circuits or brief circuits. Furthermore, examining sensors, actuators, and passes on for appropriate performance is essential in diagnosing electrical malfunctions accurately.

On the mechanical front, troubles like jams, misalignments, or extreme resonances can disrupt packaging procedures. To resolve mechanical issues, carry out a comprehensive aesthetic examination of moving parts, belts, chains, and gears for indications of wear or damages. Lubrication of vital components can avoid friction-related issues and make certain smooth machine operation. Verifying the alignment of components and adjusting stress go to these guys where essential can fix concerns connected to imbalances or irregular activities in the product packaging equipment. By incorporating a systematic technique with an in-depth understanding of the maker's functions, effective troubleshooting of electrical and mechanical problems can be attained, decreasing downtime and maximizing manufacturing outcome.

Optimizing Maker Settings for Effectiveness

To improve the general performance of packaging machines, a crucial aspect involves fine-tuning and maximizing equipment setups for maximum efficiency and output uniformity. Effectively adjusted device settings can significantly influence the rate, accuracy, and quality of the product packaging procedure. One essential aspect to think about is changing the device's rate setups to find the optimal equilibrium between productivity and accuracy. By fine-tuning the speed, you can avoid issues such as jams or misaligned product packaging. Furthermore, adjusting the stress settings, consisting of the sealing and reducing pressures, is essential for ensuring that bundles are sealed safely without damaging the products. her latest blog Guaranteeing the correct temperature level settings for securing elements such as warm sealants or thermal transfer printers is likewise essential to additional hints keep the integrity of the product packaging. Frequently monitoring and changing these equipment settings based upon the specific demands of the product packaging materials and item can lead to boosted efficiency, decreased downtime, and boosted overall outcome top quality.

Executing Preventive Maintenance Actions

Implementing preventive upkeep procedures is vital for making sure the longevity and optimum performance of product packaging makers in commercial settings. This schedule needs to be complied with vigilantly by qualified maintenance employees to make sure that the machines run at peak efficiency.

In enhancement to arranged upkeep, it is vital to maintain extensive documents of all maintenance tasks done on the packaging devices. These records can offer valuable understandings into the equipments' efficiency patterns, aid recognize persisting concerns, and guide future maintenance efforts - packaging machine repair. In addition, purchasing training programs for maker operators and maintenance team on proper maintenance treatments and techniques can dramatically enhance the efficiency of preventative maintenance procedures. By focusing on preventive maintenance, organizations can prolong the life expectancy of their product packaging machines, reduce disruptions in production, and keep constant item high quality.

Final Thought

In verdict, efficient troubleshooting of common problems in packaging maker procedure entails recognizing troubles, executing regular upkeep checks, troubleshooting mechanical and electrical issues, optimizing device settings for efficiency, and executing preventive maintenance steps. By following these steps, drivers can guarantee reliable and smooth procedure of product packaging equipments, decreasing downtime and making the most of productivity.

When troubleshooting packaging machine troubles, it is critical to precisely determine common issues that might develop during the packaging procedure.Efficient troubleshooting of electrical and mechanical troubles in product packaging devices requires an organized technique and a deep understanding of the device's components and procedure.To improve the overall efficiency of product packaging devices, a crucial facet includes fine-tuning and optimizing equipment settings for maximum performance and output consistency.Applying precautionary maintenance steps is crucial for ensuring the durability and optimal efficiency of packaging makers in industrial setups.In addition to arranged maintenance, it is important to keep detailed records of all upkeep activities done on the packaging makers.

Report this page